Overview

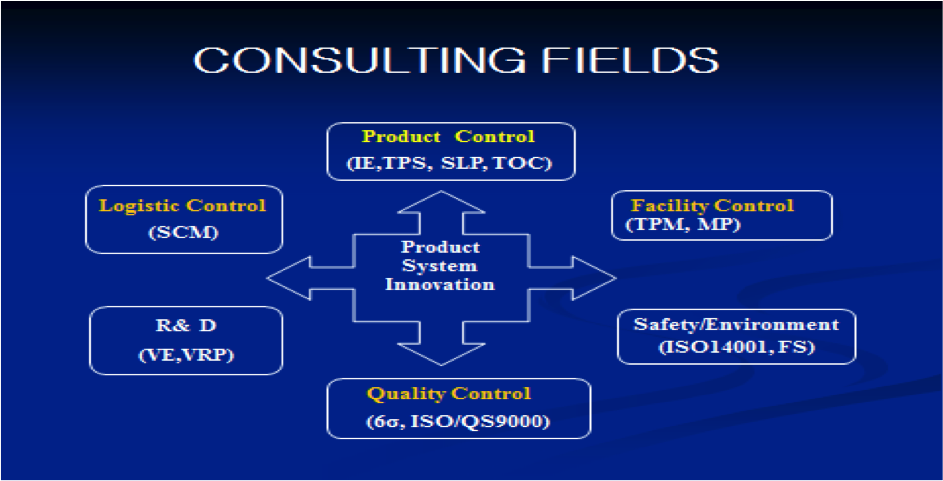

We provide consulting of improvement of the shipyard productivity, equipment support and planning / design of production plants and ship building

- Improvement of productivity

- Plan and design consulting of new shipyard

- Consulting of product equipments and equipments designing

- Consulting of ship building

Shipyard feasibility study

- Business Structure Study

- Profit Structure Analysis

- Investment & Operating Cost Calculation

- Future Financial Statments

- Risk Analysis

- Sensitivity Study

- Valuation Calculation

Shipyard engineering study

- Capacity Calculation by Shop & Equipment

- Target Production of shipyard

- Conceptual Technical Engineering

- Outline Specification of Facilities & Equipment

- Shipyard Layout

Shipyard production consulting

- Production Planning

- Manpower Planning

- Process Management

- Load Analysis & Balancing

- WBS & Work Order System

- Pallet System

- Material Transfer Management

- Technical Method Development

| WORK | DESCRIPTION | PLACE |

|---|---|---|

| Design | The design is generally classified into hull design and the outfitting design, and each design is phased as the concept design, basic design, detail design and construction design. | Design Lab |

| Pre-preparation | Various steel material manufactured to suit the design standard is transported by ship or car, and is kept on the steel stock yard, and the steel is classified by the construction process. The steel delivered from the steel stock yard passed through a pre-preparation process removing the rust and rust prevention painting in pre-preparation shop for rust prevention. | Hull Shop |

| Cutting off | The pre-prepared steel is cut off by the full automatic cutting machine according to the numeral information of the drawing. | Hull Shop |

| Fabricating | The cut-offed steel is fabricated to the curved form-shape or the right angle-shape according to the required form-shape and sent to the assembling process line. | Hull Shop |

| Block assembling | The fabricated steel which is cut and floded or bent according to the drawings is classified to utilize in the ship tailpiece. And the block fabrication is phased as Unit-block assembling. Sub-block assembling and Block assembling in each fabrication yard according to the process, and is classified as the curved block and the panel block typically. | Each Yard for Hull Shop |

| Pre-outfitting | A process to install the pipes, structures and accessory equipment to the assembled block before erection. | Pre-outfitting Shop |

| Painting | The rusted parts of the assembled pre-outfitting block during the production process is removed and painted. | Painting Shop |

| Pre-erection | Before erecting the fabricated and painted block at dock, there is a process to make the block into the big size. Two or three block are incorporated into the big size Ultra block to the extent of the lift-able capacity by crane. | Pre-erection Shop |

| Erection | The block which is assembled, pre-outfitted, painted and pre-erected is finally lifted and settled at the dock by Goliath crane. | Dock |

| Launching | The ship of which the hull is built in the dock, after having passed the various inspections, is first launched on the water. | Dock |

| Outfitting | After the launching the ship is tied to the quay wall the inside interior outfitting and mechanical equipment installing work are performed. | Quay Wall |

| Pre-operation | After the outfitting works are completed, the performance test for the main engine, generator, boiler, and ship speed etc, is done according to the design specification and the contract specification under the real voyage circumstances for the overall performance of the ship. | Sea |

| Delivery | When the ship is constructed without problems according to the drawing and contract specification, the ownership of the ship is handed over to the ship owner. | The place for the delivery |

- Modular transporter

- Blasting and painting shop system(including equipments)

- Auto-moving Work-way system

- Big-Door / Crane / Welders / insulation paint and etc

- Support of special ship collaboration production and technology transfer agreement

- Support of major equipments / equipments section and supply